3D Print Problems: Difference between revisions

| Line 72: | Line 72: | ||

Get a piece of 80g/m² paper ready. | Get a piece of 80g/m² paper ready. | ||

# Auto Home from the Marlin menu: Prepare/Auto home | # Auto Home from the Marlin menu: Prepare/Auto home | ||

# You might want to loosen all four screws until you feel no more resistance. Looking from the top you turn the screws clockwise. Your hands have to move counter-clockwise since the screws are below the plate. | # You might want to loosen all four screws until you feel no more resistance - do not turn much further or the screws will come completly off. Looking from the top you turn the screws clockwise. Your hands have to move counter-clockwise since the screws are below the plate. | ||

# Start the leveling procedure from the Marlin menu: Prepare/Level corners. Make sure the paper is squeezed by the extruder in the corresponding corner. At this time the corners should be too tight. In the first "round" - 4 x time "next corner" tighten the screws until you feel some resistance from the screws. Don't worry about the amount of resistance of the paper on top yet - it should just be tight. | # Start the leveling procedure from the Marlin menu: Prepare/Level corners. Make sure the paper is squeezed by the extruder in the corresponding corner. At this time the corners should be too tight. In the first "round" - 4 x time "next corner" tighten the screws until you feel some resistance from the screws. Don't worry about the amount of resistance of the paper on top yet - it should just be tight. | ||

# Now loosen the resistance on the paper by turning the screws counter-clockwise (moving your hand clockwise). The paper should just not move freely - a little bit of "rest-resistance" should be feelable. | # Now loosen the resistance on the paper by turning the screws counter-clockwise (moving your hand clockwise). The paper should just not move freely - a little bit of "rest-resistance" should be feelable. | ||

Revision as of 08:18, 25 February 2019

General

- https://www.simplify3d.com/support/print-quality-troubleshooting/

- http://www.geeetech.com/blog/2016/12/troubleshooting-guide-to-19-common-3d-printing-problemspart-one/

Checklist

Some of the problems described here can be avoided by observing the 3D Print Checklist

Print Aborted

Running out of filament

The amount of initial filiament shipped with my Geeetech_A10 was simply not enough to finish the print job:

Rebooting computer while USB is connected

When installing a new USB driver the computer rebooted - it's probably the same if you unplug and plug the USB cable while printing from SD card:

Underextrusion

See e.g.

- https://www.raise3d.com/pages/extruding-too-little-much-plastic

- https://ultimaker.com/en/resources/21477-how-to-fix-under-extrusion

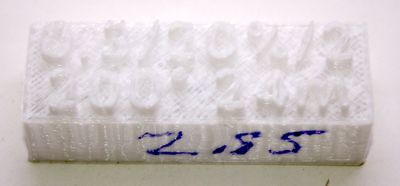

in my case it happened when I set the Filament settings in the marlin menu with "E in mm3" to 1.75. This was a misunderstanding that lead the software to assume my filament was flowing faster than it was. After switching the volumentric value off things were much better. The same will happen if you use the default Material/filament size in Cura which might be wrongly set to 2.85 mm instead of 1.75 mm for the filament you might be using.

The 3D_Print_Testbox print clearly shows the difference:

Clogged Nozzle

See e.g.

Print stuck to glass / print bed

I had best results with the temperature method in combination with taping the bed before printing. With a minus 17 degree cooling pad from the deep fridge below the glas bed and a gentle stroke with the rubber hammer the problem usually went away within a minute.

Stringing

see e.g.

Slight stringing can simply be sanded off:

Shifting layers / Layer shifting

- https://help.prusa3d.com/article/v40kdhc9rk-layer-shifting

- https://forums.matterhackers.com/topic/76/how-to-fix-shifting-layers

- https://www.geeetech.com/forum/viewtopic.php?p=87959&sid=1f0175e82a10a863b927e1272ffdb257

Changing filament

Pillowing

- https://all3dp.com/2/3d-printing-top-layer-problems-easy-fixes-for-pillowing/

- https://rigid.ink/blogs/news/pillowing-stringing-and-splitting-what-they-are-and-how-to-stop-them

- https://www.raise3d.com/pages/holes-and-gaps-in-solid-layers

Bed Leveling

Geeetech A10 Bed Leveling

Initial be leveling

Get a piece of 80g/m² paper ready.

- Auto Home from the Marlin menu: Prepare/Auto home

- You might want to loosen all four screws until you feel no more resistance - do not turn much further or the screws will come completly off. Looking from the top you turn the screws clockwise. Your hands have to move counter-clockwise since the screws are below the plate.

- Start the leveling procedure from the Marlin menu: Prepare/Level corners. Make sure the paper is squeezed by the extruder in the corresponding corner. At this time the corners should be too tight. In the first "round" - 4 x time "next corner" tighten the screws until you feel some resistance from the screws. Don't worry about the amount of resistance of the paper on top yet - it should just be tight.

- Now loosen the resistance on the paper by turning the screws counter-clockwise (moving your hand clockwise). The paper should just not move freely - a little bit of "rest-resistance" should be feelable.

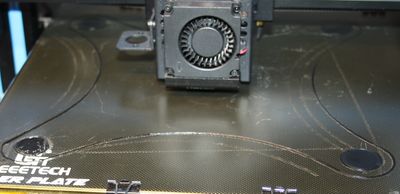

Testing with some gcode

The front left corner ist not o.k.

Support

https://pinshape.com/blog/dotm-fantasy-graph-3d-printer-support-structures/

Speed

Speed, Quality, Strength, Cost - pick any two ...

Support break down

Test Cube

See 3D Print Testbox