"""

stepper.py

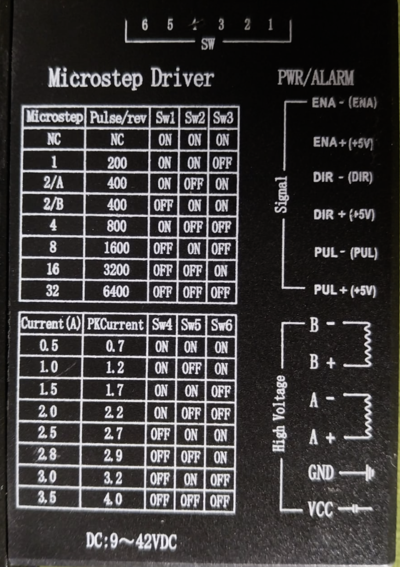

Control two stepper motors connected to a Raspberry Pi through a TB6600 driver to sprinkle a lawn.

Author: Wolfgang, ChatGPT, Claude AI

Date: 2024-07 to 2024-08

"""

import RPi.GPIO as GPIO

import time

import argparse

from typing import Dict

class StepperMotor:

def __init__(self, name: str, ena_pin: int, dir_pin: int, pul_pin: int, steps_per_revolution: int = 200):

self.name = name

self.ena_pin = ena_pin

self.dir_pin = dir_pin

self.pul_pin = pul_pin

self.steps_per_revolution = steps_per_revolution

self.setup_gpio()

def setup_gpio(self):

GPIO.setup(self.ena_pin, GPIO.OUT)

GPIO.setup(self.dir_pin, GPIO.OUT)

GPIO.setup(self.pul_pin, GPIO.OUT)

GPIO.output(self.ena_pin, GPIO.HIGH) # Start with motor disabled

def enable(self):

GPIO.output(self.ena_pin, GPIO.LOW)

def disable(self):

GPIO.output(self.ena_pin, GPIO.HIGH)

def set_direction(self, clockwise: bool):

GPIO.output(self.dir_pin, GPIO.HIGH if clockwise else GPIO.LOW)

def step(self, steps: int, delay: float):

for _ in range(abs(steps)):

GPIO.output(self.pul_pin, GPIO.HIGH)

time.sleep(delay)

GPIO.output(self.pul_pin, GPIO.LOW)

time.sleep(delay)

class Move:

def __init__(self):

GPIO.setmode(GPIO.BOARD)

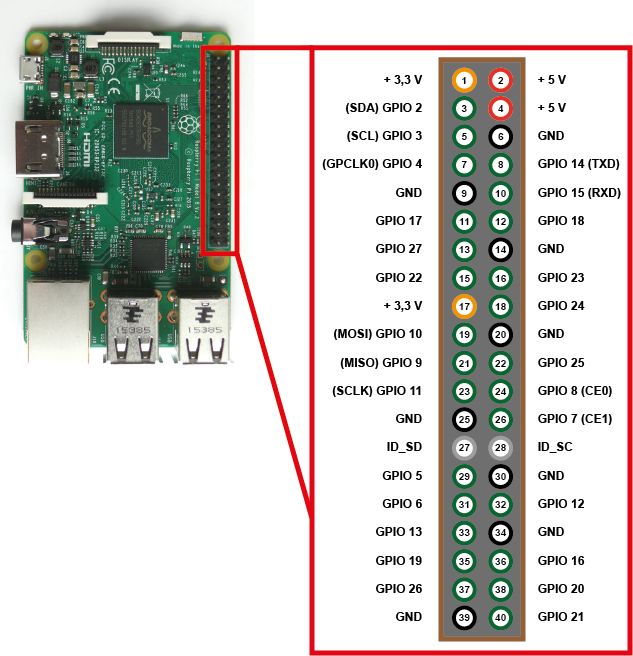

self.motors: Dict[int, StepperMotor] = {

1: StepperMotor("Motor1", 37, 35, 33),

2: StepperMotor("Motor2", 31, 29, 23)

}

def enable_motor(self, motor_id: int):

motor = self.motors.get(motor_id)

if motor:

motor.enable()

else:

print(f"Motor {motor_id} not found")

def disable_motor(self, motor_id: int):

motor = self.motors.get(motor_id)

if motor:

motor.disable()

else:

print(f"Motor {motor_id} not found")

def move_motor(self, motor_id: int, angle: float, speed_rpm: float, keep_enabled: bool = False):

motor = self.motors.get(motor_id)

if not motor:

print(f"Motor {motor_id} not found")

return

steps = int(abs(angle) / 360 * motor.steps_per_revolution)

delay = 30 / (speed_rpm * motor.steps_per_revolution)

motor.enable()

motor.set_direction(angle >= 0)

motor.step(steps, delay)

if not keep_enabled:

motor.disable()

def perform_pattern(self,

horizontal_angle: float,

horizontal_steps: int,

vertical_angle: float,

rpm: float):

# Enable both motors before starting the pattern

self.enable_motor(1)

self.enable_motor(2)

for _ in range(horizontal_steps):

self.move_motor(1, horizontal_angle, rpm, keep_enabled=True)

self.move_motor(2, vertical_angle, rpm, keep_enabled=True)

self.move_motor(2, -vertical_angle, rpm, keep_enabled=True)

# Reset horizontal position

self.move_motor(1, -horizontal_angle * horizontal_steps, rpm, keep_enabled=True)

# Disable both motors after completing the pattern

self.disable_motor(1)

self.disable_motor(2)

def perform_pattern_by_args(self, pattern_args):

# Default values

params = {

'steps': 80,

'hangle': 160,

'vangle': 120,

'rpm': 10

}

# Parse provided arguments

for arg in pattern_args:

key, value = arg.split('=')

if key in params:

params[key] = float(value)

# Execute the pattern

self.perform_pattern(

horizontal_angle=params['hangle'] / params['steps'],

horizontal_steps=int(params['steps']),

vertical_angle=params['vangle'],

rpm=params['rpm']

)

def cleanup(self):

for motor in self.motors.values():

motor.disable()

GPIO.cleanup()

time.sleep(0.1)

# Modify main function to use the new approach

def main():

parser = argparse.ArgumentParser(description="Control stepper motors")

parser.add_argument("-m", "--motor", type=int, default=1, help="Motor ID (default: 1)")

parser.add_argument("-a", "--angle", type=float, default=15, help="Angle to rotate (default: 15, positive for CW, negative for CCW)")

parser.add_argument("-r", "--rpm", type=float, default=20, help="Speed in RPM (default: 20)")

parser.add_argument("-k", "--keep-enabled", action="store_true", help="Keep motor enabled after movement")

parser.add_argument("-p", "--pattern", nargs='*', metavar="KEY=VALUE",

help="Perform pattern: [steps=N] [hangle=DEG] [vangle=DEG] [rpm=RPM] default: steps=20,hangle=160,vangle=90,rpm=10")

args = parser.parse_args()

move_controller = Move()

if args.pattern is not None:

# For pattern, we'll handle enabling/disabling within the perform_pattern method

move_controller.perform_pattern_by_args(args.pattern)

else:

# For single motor movement

move_controller.move_motor(args.motor, args.angle, args.rpm, args.keep_enabled)

move_controller.cleanup()

if __name__ == "__main__":

main()

#!/bin/bash

# Bash script to control a two-motor garden hose system for watering a lawn

# Utilizes the updated stepper.py to turn two motors

# Define the path to your stepper.py script

STEPPER_SCRIPT_PATH="./stepper.py"

python3 $STEPPER_SCRIPT_PATH -p

To control the stepper motor directly:

sudo python3 stepper.py --angle 90 --direction left --frequency-hz 500 --rpm 30

sudo is necessary for accessing the kernel memory directly.

This will run 10 cycles of watering. Adjust the number as needed.